Geothermal Technologies – Basic Operating Overview

The selection of your Heating, Ventilation, and Air-Conditioning (“HVAC”) system is one of the most important decisions that will be made regarding your home or business. Ultimately, the ability to make a sound decision will rest upon your level of understanding regarding the subject matter. Believe it or not, the fundamental principals of geothermal technologies are not hard to understand. The following material has been compiled to provide you with a basic understanding of the principals that allow heat pumps to work. We are quite confident that you will be even more impressed with ETA geothermal systems after learning a bit more about the basics of geothermal technologies.

Basic Principals of geothermal technologies

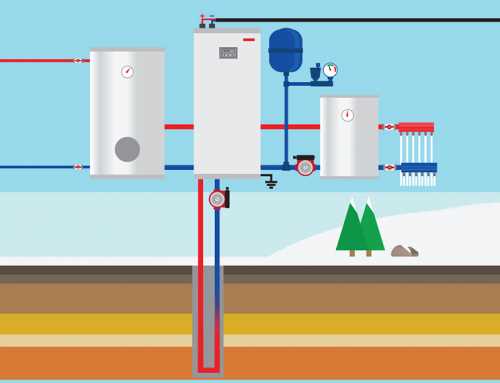

Mankind eventually discovered that they could neither create nor destroy the energy God had created, but they could change the energy from one form to another. Scientists now refer to this discovered principle as the first law of thermodynamics. ETA systems utilize basic heat pump principals, with innovative, advanced, and patented designs that take advantage of stable geothermal temperatures to provide the most advanced heating and cooling systems known to exist. A heat pump is an electrically operated machine that provides heat by compressing a vapor and raising its temperature. Cooling is provided by expanding a vapor and lowering its temperature. ETA utilizes these principals along with the first law of thermodynamics to provide the most efficient geothermal technologies known to exist.

For example, if one compresses 1 cubic yard, or 1 cubic meter, of a vapor that is 55° F (13° C) into only 1 cubic inch, or centimeter, the pressure of the vapor is greatly increased, and so is the temperature. All of the heat energy that was formerly in a large area is condensed into a much smaller area, so the temperature is much higher. Conversely, if one expands 1 cubic inch, or 1 cubic centimeter of vapor that is 55° F into a much larger areas such as 1 cubic yard, or meter, the pressure of the vapor is greatly decreased, and so is the temperature. All of the heat energy that was formally in a small area is expanded into a much larger area, so the temperature is much lower. Thus, a heat pump can raise the temperature of a 55° F (13° C) vapor up to 150° F (66° C) by simply compressing the vapor via the use of a compressor. Likewise, a heat pump can lower the temperature of a 55° F (13° C) vapor down to 20° F (-7° C) by expanding the vapor through an expansion device.

Heat pumps operate utilizing these basic principles of vapor compression and expansion, together with the factual law of physics that heat flows to cold (Fourier’s Law of conduction heat transfer). For example, if you hold a cold cup of water in your hand, the “cold” feeling will begin to dissipate as the “warmth” of your hand travels into the cold cup of water (actually raising the temperature of the water). Your hand feels cold because heat is flowing out of your hand. If heat were flowing into your hand from a hot cup of coffee, your hand would feel hot. It is these basic principals that allow a typical and constant 55° F (13° C) temperature beneath the surface of the earth to be used to heat and cool the air within your home or business. Applying the Principals to ETA Geothermal Technologies

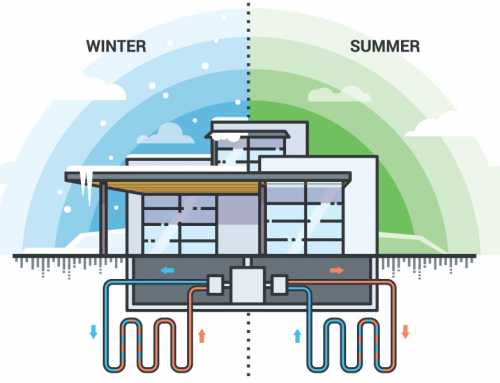

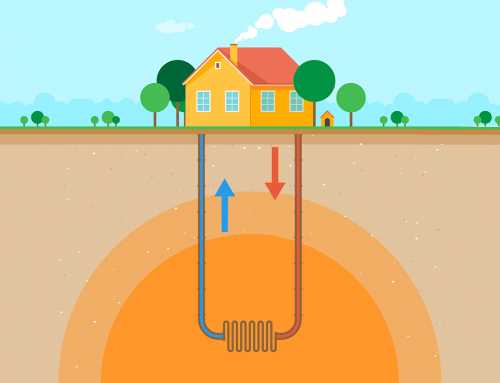

Heating Mode

In the winter, an expanded and cold vapor refrigerant circulated within highly heat conductive copper tubing and absorbs the approximate 55° F (13° C) heat naturally supplied by the earth. This 55° F (13° C) heated refrigerant vapor is compressed, and the resulting now hot vapor is circulated within an air handler, where the cold return air from your house or business is also circulated by means of an electric fan. An air handler is simply a box within with finned tubing and a fan. The cold interior “return” air from your home or business is blown across the finned tubing by the electric fan. In the heating mode, the finned copper tubing is hot, containing the refrigerant vapor that has been compressed by the system’s vapor compressor. The heat from the hot vapor circulating within the finned tubing inside the air handler is naturally absorbed by the colder air. (Remember the principal that heat will always travel to cold). The now warmed air is blown into your home or business through “supply” air ductwork via the electric fan within the air handler.Thus, the heat supplied for your interior air is supplied by the natural and renewable temperature of the earth’s crust, for free. Your only expense is the cost to operate a compressor to raise the temperature of the free heat, and the cost to operate a fan to transfer the heat into your interior air.

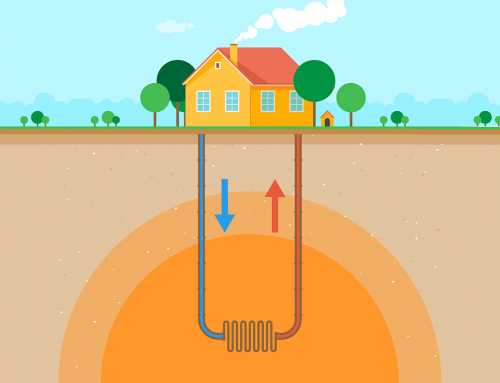

Cooling Mode

In the cooling mode, the refrigerant vapor is circulated in a reverse direction, with the hot compressed vapor being sent in the earth, where the excess heat is naturally absorbed and taken away by the much cooler sub-surface temperature. For example, you may have a hot vapor with a temperature of 120° F (49° C) leaving the compressor unit and traveling into the underground copper ground source heat exchanger. This 120° F (49° C) is much hotter than the 55° F (13° C) ground. If we again apply the principal that heat will always travel to cold, we can understand that the ground will remove the heat and begin to cool down the hot refrigerant vapor. With the excess heat in the refrigerant vapor removed by the earth, the cooled refrigerant actually condenses into a liquid. The cooled liquid refrigerant is then expanded, by means of an expansion device, into a lower pressure, which causes the temperature of the refrigerant to drop even lower. The now cold refrigerant is next circulated through the finned tubing within the air handler. The cold refrigerant absorbs the excessive heat from your interior air, as the heat in your air naturally travels to the colder refrigerant. Your now cooled air is circulated back into your home or business. The refrigerant that has absorbed the excessive heat from you interior air now expands back into a vapor. The warmed vapor, having absorbed the exceed heat from your interior air, is compressed by the vapor compressor, and the temperature of the refrigerant vapor is greatly increased. This resulting hot vapor is sent into the ground where the excess heat is removed and the process is repeated. Again, your home/business is cooled via the simple expenditure of energy that is only necessary to operate a compressor and the fan in your air handler.

Air-Source Heat Pump

An air-source heat pump basically operates in the same manner. However, there are several problems.

- The first problem is that the outside temperature is not stable, and may be subject to significant temperature fluctuations. Thus, when it is very cold outside, there may not be enough heat in the air for the system to efficiently operate on its own (a lack of adequate temperature differentials between the cold refrigerant circulating in finned tubing and the cold outside air to which the refrigerant tubing is exposed). For example, if the refrigerant temperature circulating within the finned tubing exposed to the outside air is 20° F (-7° C), and the outside air temperature is also 20° F (-7° C), the cold refrigerant has no heat to absorb from the air. In such event, expensive auxiliary heat (such as electric resistance heat, or fossil fuel heat) will be required to provide the heat that is simply not available from the air in an air-source heat pump. On the other hand, no matter how cold it gets outside, there is always plenty of free, renewable, geothermal heat within the earth’s crust for the ETA system to efficiently operate. Further, in the heating mode, the cold refrigerant, circulating within the finned outdoor tubing exposed to the exterior air, attracts moisture. This moisture condenses and freezes on the finned heat transfer tubing. As moisture continues to condense and freeze, ice builds up and blocks the airflow across the heat transfer tubing. In order to melt and remove the ice, an air-source heat pump must then operate in a “de-frost” mode. The “de-frost” mode means the heat pump has switched to a cooling mode (air-conditioning) in the winter, where the hot vapor is circulated through the exterior coils, instead of through the interior air handler, so as to melt the ice inhibiting air flow across the finned tubing. While the system’s hot vapor is being circulated through the exterior finned tubing, your interior air is being cooled…not heated. This requires supplemental/auxiliary heat to operate so as to maintain your interior air temperature while the “de-frost” cycle is in operation. Worse, frequently switching from the heating mode to the cooling mode, and vice versa, during the winter is hard on compressors and contributes to decreased system life. ETA system technologies do not require a “de-frost” cycle at all.

- Conversely, when it is very hot outside, the vapor temperature and pressures within an air-source heat pump materially rise. This creates two concerns. The first is that higher pressures can result in increased compressor power draws, and higher cooling bills. The second is that as refrigerant temperatures increase, there is less of a temperature differential between the refrigerant circulating within the finned outdoor tubing and the outdoor air, resulting in poor heat transfer and less efficient system operation when you need it the most. Since an ETA system utilizes stable geothermal temperatures within which to reject its waste heat, no matter how hot it gets outside, an ETA system is not subject to the significant operational efficiency losses that plague air-source heat pumps. Exterior air-source heat exchangers also lose efficiency when clogged with leaves, grass, insects, etc., in the summer. These problems are non-existent with an ETA system.

- Air-source heat pumps require an exterior unrestricted airflow around their finned tubing exposed to the air. An ETA system’s geothermal, sub-surface, heat exchange tubing does not require any above-ground airflow. Thus, the attendant concerns with an air-source heat pump in this regard are non-existent with an ETA system.

- Air-source heat pumps require the operation of an exterior fan. An ETA system requires no exterior fan and, consequently, has no exterior fan power draw operational expense, and no exterior fan maintenance/replacement concerns.

Summary

With an ETA system, the ground actually works for you, tirelessly and without charge, to provide your heating and cooling needs. Your bills are extremely low because you only pay for the small amount of power necessary to operate a compressor and a fan.Further, since there is no open flame, as with fossil fuel-based systems, there is no flue venting requirement, there is not danger of explosion, there is not danger of carbon monoxide poisoning, and the air is not uncomfortably dried out. The ETA system is very safe, and is environmentally friendly. The fact that ETA systems have only two primary moving parts (a compressor and a fan) result in the systems requiring minimal service requirements. ETA believes it has the most efficient and most comfortable heating/cooling system in the world, bar none. This belief is supported via both detailed laboratory tests and independently certified in-field results.

Earth River Geothermal, Inc.

©2007-2017

Geothermal Heating & Cooling Contractor, Annapolis, Maryland